Minimising the Handling Cost in "Process Oriented Layout. Lecture # 08

Автор: Technical Peaks

Загружено: 2020-06-29

Просмотров: 19977

Описание:

0:00 Process Oriented Layout

0:52 Introduction to handling cost

3:33 Equation for handling cost

6:08 Problem/Example

6:45 Number of units table

14:24 Problem Conditions

18:10 solution to the problem

20:16 Initial cost calculations

24:17 Minimizing the handling cost

28:42 Minimized handling cost Calculation

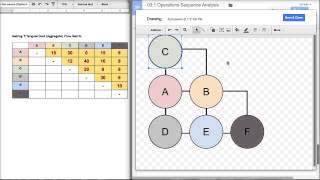

▶A machine shop, consisting of 6 distinct production areas is planning to

redesign its layout. The building is 90 feet long and 40 feet wide, with all

production areas of equal size. The material handling equipment being

used can only move clockwise on marked pathways, with loading/

unloading possible only at the center of the production area. The pathways

have only been marked horizontally and vertically and no diagonal

movement of the loads between departments is possible. Management

has estimated that the cost of moving a single load in the facility is $1 for

every 10 feet. Flow matrix between different departments over the last

month and current layout are given.

▶ Design two layouts aimed at reducing the total material handling cost.

In the process layout we try to minimize the handling cost. The cost associated with the handling might be different from one route to another route. To minimize this cost by adjusting the position of each working cell or processes.

Movement of the equipment or the parts from one process to another process is associated with a certain cost. This cost vary from process to process based on the distance between each processes.

Now this is the technique that we use for minimizing the overall cost of the movement from one process to another process.

Повторяем попытку...

Доступные форматы для скачивания:

Скачать видео

-

Информация по загрузке:

![Plant Layout, Objectives of Plant Layout, Types of Plant Layout [Animated video]](https://ricktube.ru/thumbnail/4vq0FKWYud8/mqdefault.jpg)