Formlabs Rigid 10K Resin vs Rigid 4000 Resin. Which Material Is Right for You?

Автор: Center 3Dprint

Загружено: 2022-06-29

Просмотров: 3196

Описание:

Formlabs Rigid 10K Resin vs Rigid 4000 Resin.

Formlabs Rigid Resins for SLA/LFS 3D Printing

The family of Rigid Resins have many shared applications. Identifying the best material for a specific use case involves understanding your design constraints and the key tradeoffs between the materials.

Which Material Is Right for You?

Trying to choose a material within our Rigid family? A good place to start is the tensile modulus which is a measure of stiffness. A higher tensile modulus indicates a stiffer material.

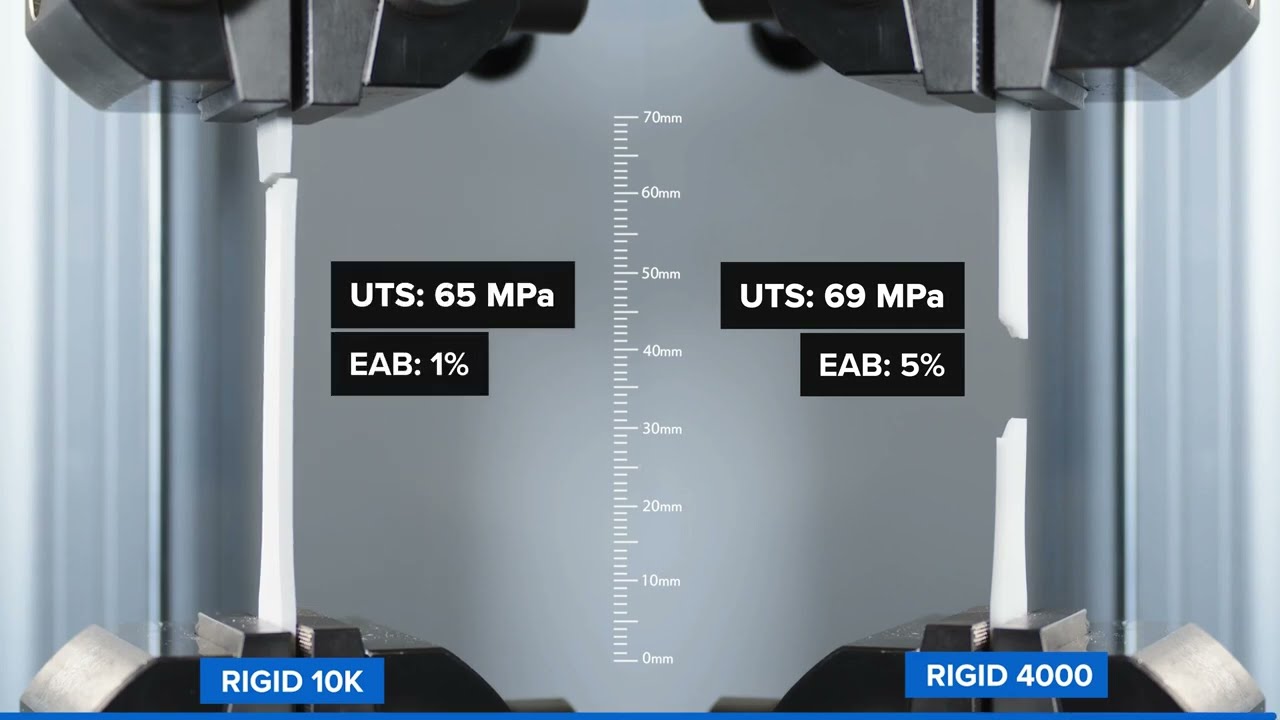

Rigid 10K

Rigid, Strong, Industrial-Grade Prototypes

This highly glass-filled resin is the stiffest material in our engineering portfolio. Choose Rigid 10K Resin for precise industrial parts that need to withstand significant load without bending. Rigid 10K Resin exhibits a smooth matte finish and is highly resistant to heat and chemicals.

✅ Short-run injection mold masters and inserts

✅ Heat resistant and fluid exposed components, jigs, and fixtures

✅ Aerodynamic test models

✅ Simulates stiffness of glass and fiber-filled thermoplastics

Rigid 4000

Stiff, Strong, Engineering-Grade Prototypes

Glass-filled Rigid 4000 Resin prints with a smooth, polished finish and is ideal for stiff and strong parts that can withstand minimal deflection. Consider Rigid 4000 Resin for general load-bearing applications.

✅ Mounts and brackets

✅ Thin-walled parts

✅ Jigs and fixtures

✅ Simulates stiffness of PEEK

👇 Visit Our Website

➥ https://center3dprint.com/en/

Повторяем попытку...

Доступные форматы для скачивания:

Скачать видео

-

Информация по загрузке: